2 Filling Heads Nespresso Capsule Filling Machine

1) Rotary type, full automatic, pneumatic control.

2) 3 emergency stop buttons

3) Glass cover as standard

4) Nitrogen flushing after capsule loading, flushing before foil loading, flushing after foil loading, flushing into filling hpper

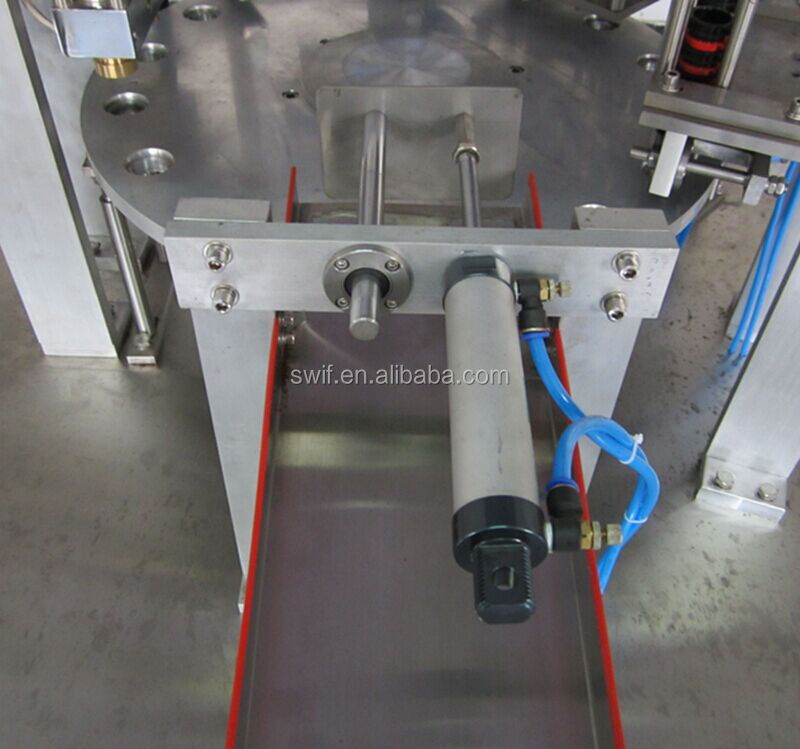

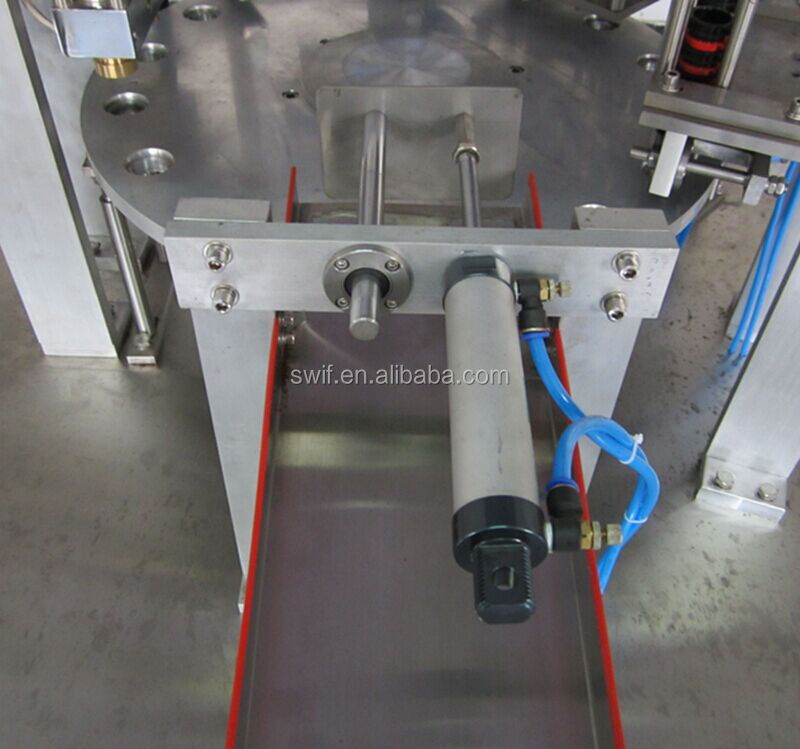

5) Working process: Capsule loading, coffee filling, coffee pressing, hopper mixing, capsule edge cleaning, nitrogen flushing, foil loading, sealing, sealed capsules pushing-out.

Capsule Loading system Filling system

Foil loading system Sealing system

Sealed capsule pushing All parts

Function of nespresso capsule filling machine:

1. Automatic cup falling:Artificial barrier cup fold in automatic cup rack, machine automatic cup falling to the line in the template

2. The nitrogen filling:Under the direct charge to squeeze type filling nitrogen (due to the proportion of nitrogen is greater than the air)

3. The filling Cylinder filling capacity: 15 ~ 25 kg;

Filling cylinder adopts the principle of barrel type clean and replace easily;

All parts contacting material is 304 stainless steel material;

Filler material using vibration compaction + screw + (K - CUP compaction).

4. Automatically put film:Membrane made suction-cup to grab, flat sealing membrane

5. The sealing way:copper sealing heads,using thermostatic sealing, sealing twice, pneumatic cylinder control

6. Automatic out of the cup:The pusher type off the cup

Feature of nespresso capsule filling machine:

1.Specially designed for coffee products (or other kinds of powder products, such as tea powder, cocoa powder etc. ) to be filled and sealed.

2.Applied with world famous electrical and pneumatic components.

3.All the parts of machine contact with powder are made of stainless steel.

4.PLC touch screen control with English and Chinese languages.

5.Whole machine cover by glass.